Baoji Hong Ya Da Nonferrous Metal Materials Co.,Ltd.

Add: No.85,Baotai Road,High-tech Development Zone,Baoji City,Shaanxi,China.721013

Contact:Ms.carrolyn

Mob/We chat/ Whats app: +86-15191772362

Tel:0086-917-3854158

Email:carrolyn@hydtitanium.com

Skype:carrolyn851

QQ:379855550

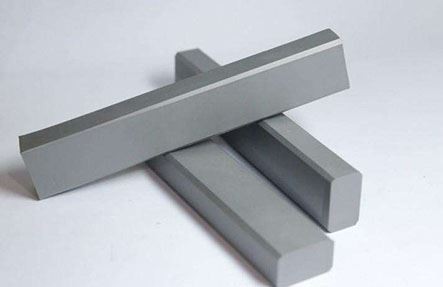

Tungsten carbide has high strength and good wear resistance, and is widely used in various manufacturing industries: The downstream applications of tungsten carbide in the world are mainly: cutting tools, wear-resistant parts, high-pressure tools, mining tools and other fields. In 2018, China's cemented carbide product structure mainly consisted of bars (34%), cutting inserts (18%), mining alloys (20%), wear-resistant parts (26%), etc. In the future, with the steady growth of demand for high-performance cemented carbide from basic industrial industries such as cutting machine tool industry, mining industry, automobile manufacturing, and oil drilling industry, as well as the continuous expansion of emerging manufacturing fields, China's tungsten industry will continue to transform and upgrade. The cemented carbide market will achieve rapid breakthroughs.

The CNC rate of metal cutting machine tools has increased, and high-end cemented carbide tools are expected to drive demand: cutting tools account for 18% of China's cemented carbide product structure, and its consumer output value accounts for 65%, which is one of the fields with the highest added value. At present, cutting tools are mainly realized by relying on machine tools. From 2017 to 2018, China's metal cutting machine tool consumption remained above 18 billion U.S. dollars, and the export value in 2018 was 2.66 billion U.S. dollars, a year-on-year increase of 22%. With the increase in the CNC rate of metal cutting machine tools and the diversification of the types of prepared tools, the field of carbide CNC blades in cutting tools has developed rapidly. According to statistics from the Tungsten Industry Association, China's cemented carbide CNC blade manufacturers have grown from one in 2010 to 35. In 2018, the output of CNC blades reached 205.987 million, an increase of 5.19 times compared with 2010. The acceleration of the high-end manufacturing process in the future is expected to promote the vigorous development of high-end cemented carbide tools and drive the steady increase in tungsten consumption.

Terminal applications of tungsten are mainly concentrated in transportation, mining equipment and industrial manufacturing: terminal applications of tungsten products cover transportation, mining equipment, industrial manufacturing, auto parts, energy consumption, national defense and military industries. With the development of my country's high-end manufacturing industry and the recovery of infrastructure, energy and other industries, the demand for high-end cemented carbide has increased, driving the continuous growth of tungsten consumption.

From the demand side, the tungsten market demand in 2019 will continue to maintain a low-speed growth trend. With the easing of Sino-US trade frictions and the recovery of confidence in the international tungsten market, foreign tungsten demand is expected to maintain a stable level; in the medium and long term, as China's economy picks up, equipment manufacturing, infrastructure and other fields continue to grow, tungsten market demand is expected to maintain its boom .

Baoji Hong Ya Da Nonferrous Metal Materials Co.,Ltd.

Add: No.85,Baotai Road,High-tech Development Zone,Baoji City,Shaanxi,China.721013

Contact: Ms.carrolyn

Mob/We chat/ Whats app: +86-15191772362

Tel:0086-917-3854158

Email:carrolyn@hydtitanium.com

Skype:carrolyn851

QQ:379855550

We sincerely welcome friends from all over the world to cooperate with us on the basis of long-term mutual benefits. We are looking forward to receiving your enquiries soon.

QR Code