Baoji Hong Ya Da Nonferrous Metal Materials Co.,Ltd.

Add: No.85,Baotai Road,High-tech Development Zone,Baoji City,Shaanxi,China.721013

Contact:Ms.carrolyn

Mob/We chat/ Whats app: +86-15191772362

Tel:0086-917-3854158

Email:carrolyn@hydtitanium.com

Skype:carrolyn851

QQ:379855550

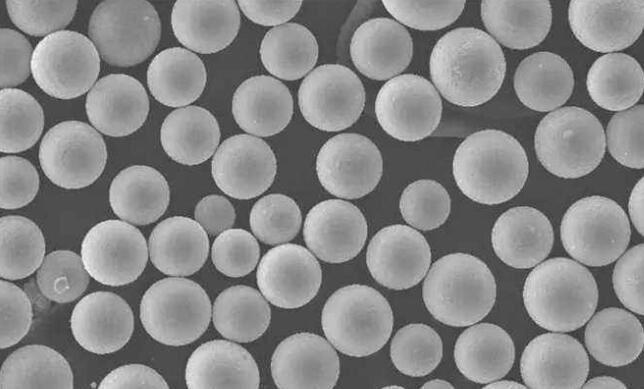

Ultra-high Speed Plasma Rotating electrode (SS-PREP)

Traditional plasma rotary electrode technology (PREP) was invented by Nuclear Metals/Starmet and later acquired by TIMET. Traditional PREP technology using rod electrode as cathode, transferred arc plasma torch as the anode, stimulate the argon gas that the ionization of argon ion of so high temperature melting form liquid membrane electrode rod end face, and then through the axis of rotation of the centrifugal force to form metal spherical particles, the rotating speed in 14000 ~ 16000 r/min, the blessing of the bar is close to the motor end exposed to air, to the atmosphere of the strict control. At present, the diameter of traditional PREP powder particle can only meet the grain size requirements of 90 ~ 250 m in Domestic LASER cladding deposition technology (LMD), but it is still difficult to meet the requirements of advanced high-speed laser cladding technology (DED/LENS) of 50 ~ 150 m, electron beam selective melting technology and laser selective melting technology for powder.

Argon gas atomization

According to different melting methods, Argon atomization (GA) can be divided into two processes: COLD-wall crucible (TGA) and electrode induction Argon atomization (EIGA). Cold wall copper crucible argon atomized by vacuum induction melting titanium alloy raw materials completely melt in the crucible, crucible, which can improve the metal solution serving its content uniformity, using local secondary at the bottom of the crucible induction coil to heat the metal solution, then form a stable flow, by means of high pressure of argon injection blow force the metal flow cooling to form a metal particles. Collect into the cyclone separator first, then into the metal tank. The vibrational density of TGA titanium alloy powder is 60% ~ 70% of the theoretical density. Electrode induction aeration (EIGA) directly forms a liquid flow by melting the ends of titanium alloy bars of a specific size with conical induction coils. Crucible is not contacted during the whole process, and then the powder is atomized by high-speed argon gas flow.

Plasma atomization

Plasma atomization technique first appeared in 1996, the technology transfer with high impact of plasma flame instantaneous melting titanium alloy wire diameter of about 3 mm, and use the argon plasma torch to impulse will melt blow silk material, this technology breakthrough the metal melting and argon gas atomization are integrated into the same steps, high temperature argon extend the droplet solidification time, can not only improve the metal particles spherical degree, and can reduce hollow particles proportion, its essence is still the aerosol pulverizing, but from its powder quality, yield, raw material application and so on comprehensive consideration, should belong to a kind of brand-new titanium alloy powder preparation technology.

Plasma spherification

Radio frequency plasma spheroidizing technology (that is, the plasma spheroidizing IPS or PS) by airflow to the spherical hydrogenation dehydrogenation titanium alloy powder into high density plasma flame remelting liquid particles, and rely on the droplet surface free can reduce the spontaneous process of instantaneous solidification for spherical metal particles, spheroidization rate of not less than 80% at a time, usually would still need a sorting and spheroidized again. Through strong electromagnetic coupling effect, rf plasma can induce the Joule heat effect of current to heat the airflow to high temperature, thus forming a self-sustainable plasma, which is different from the plasma used in plasma atomization technology and plasma rotary electrode technology. Plasma spheroidization technology is limited to non-spherical powder particles, so the variety of titanium alloy that can be produced is limited to pure titanium CP-TI, Ti6Al4V and a few other conventional brands. Moreover, due to two pulverizing processes, the control of impurity elements such as oxygen and nitrogen is an urgent problem to be solved.

Progress in additive manufacturing of titanium alloy powder

The plasma atomization process (PA) has the highest yield of 0 ~ 45 m and the highest utilization rate of raw material titanium wire, which is the most suitable powder preparation process for SLM. Ultra-high speed plasma rotating electrode process (SS-PREP) has the optimal powder comprehensive performance, including powder sphericity, fluidity, loose packing density and hollow particle ratio. Because of the lowest proportion of hollow particles, it has obvious advantages in the application of electron beam powder additive (EBM) and laser powder feeding additive (LMD). Ss-prep powder can cover the preparation technology of SLM, EBM and LMD powder for additive manufacturing. TGA, on the other hand, technology can use a variety of forms of titanium alloy materials, make the powder with the lowest economic cost, EIGA only use ϕ 50 mm or other size raw material of the bar, although as GA process, but the TGA process cost control is better than that of EIGA process.

Baoji Hong Ya Da Nonferrous Metal Materials Co.,Ltd.

Add: No.85,Baotai Road,High-tech Development Zone,Baoji City,Shaanxi,China.721013

Contact: Ms.carrolyn

Mob/We chat/ Whats app: +86-15191772362

Tel:0086-917-3854158

Email:carrolyn@hydtitanium.com

Skype:carrolyn851

QQ:379855550

We sincerely welcome friends from all over the world to cooperate with us on the basis of long-term mutual benefits. We are looking forward to receiving your enquiries soon.

QR Code